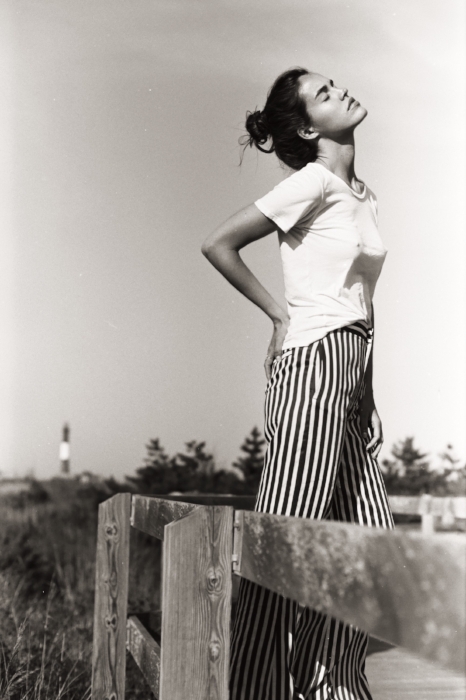

After being introduced to Groceries Apparel by a fellow model, I was immediately drawn to their simple, stylish staples that were clearly made well with the environment in mind.

I had been thinking about creating my own basic white tees at the time and while modeling was taking over much of my time, I found it difficult to balance both worlds. I created a sample tee, here in New York and after I wasn't completely content with the first mock-up, I reached out to Groceries to see if I could do an ODC edit on a tee they were already producing perfectly. I was exceptionally impressed by their openness to work with a smaller company like myself. They were flexible with their minimums and completely open about where they sourced their fabrics, where everything was made and everything in between! They're a dream to work with, and after a recent visit to L.A. I was even more impressed with how open they were on a tour of their factory.

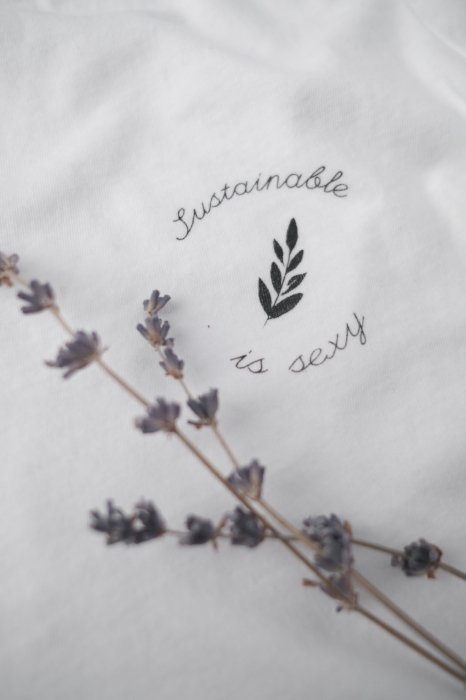

Robert Lohman, founder of the Groceries took the time to answer some in-depth questions so you can get to know a bit more about where our Sustainable Is Sexy tees come from! Check out his answers below!

1) Tell me a bit about how Groceries Apparel came about? Where did everyone in the company come from and how did you all transition into the sustainable/ethical world?

Groceries started on the Venice boardwalk with American Apparel organic blanks dyed with grass, orange juice, rust, soil, tomatoes, blood, and milk, and basically anything in my backyard. I was set on creating a non-toxic t-shirt. When I was trying to expand, it dawned on me that there were no volume blank providers that were 100% committed to chemical-free and made in USA. I had randomly met Dov Charney at a fabric store called Ragfinders and he ended up inviting me to take a tour of his American Apparel factory. Dov showed me how to sew in teams and digitize patterns. The next day I rented three Kansai Special’s and a Tukatech license. I’m not really a fashion guy, I’m an environmentalist that loves manufacturing.

2) What is your take on organic, recycled and regular cotton? Is there one the company is partial to?

From day one we’ve sourced only organic or recycled ingredients. I’m not a fan at all of regular cotton, one of the reasons we exist is to shift demand away from it. The future is in hemp, post-consumer recycled textiles, and bio-based textiles, these are some of the only fabrics that fit into a larger circular economy. Lenzing has been working on some really soft closed-loop textiles made from recycled eucalyptus fiber, like Refibra. We have some new spandex blends made from recycled ocean fishnets. There are a lot of textile innovations on the horizon made from food waste, orange peels, fish skins, coffee, etc. We also dye garments with flowers, roots, bark, leaves, and onion skins.

3) All of your clothing is made in America, which is awesome!! While I don’t think made outside the U.S. has to necessarily mean it’s a bad thing, why did you guys choose to stay local?

Locally-made is central to our business model. Being local means being closer to our garments as they are made, which helps us command the fit and quality. It also allows us to cut out middle men, trim redundancy, and lower the carbon footprint impact and costs. Being local enables us to respond and fulfill orders faster, which helps our boutique partners. Stores are able to hold their budget and analyze sales trends later into the season before purchasing. Brands that stay local don’t need to speculate their production orders, they can cut-to-order and limit waste. There are a ton of advantages to manufacturing local, made in China is great if you sell to China.

4) Tell me a bit about the factory you use and how you chose it. What’s the best way you guys ensure workers are treated well?

We are the factory. We operate our own factory to ensure our standards and values are fully executed, especially when it comes to treating our employees well. We have 80 yards of cutting space and 43 sewing machines, producing 40,000 units per month on average.

5) What’s something difficult Groceries has been able to overcome in terms of becoming more sustainable?

Early on we were passing on a lot of sales opportunities due to our higher price point and our unwillingness to manufacture non-organic garments. Groceries’ first business model relied on economies of scale in order to compete, which was hard to execute out of my garage. It was kind of a paradox in the fact that we needed more orders to feed our factory, but we were also turning down orders because we were unwilling to make a cheaper non-organic option. I was unwilling to compromise my values in order to stay in business, which sounds great but was actually a huge problem for the company. My business model stated we had to generate about 4 million dollars a year in order to feed our factory and become profitable. Groceries’ was more of a young, big business than a small business. It took me a while to convince banks and investors that my business model wasn’t insane.

6) In your opinion, what is the most unsustainable part of the fashion industry? What is GROCERIES doing to combat this?

The industry is the 2nd most toxic in the world behind oil, so I would say the toxicity. We’ve purchased 3 million yards of organic and recycled textiles to help push the demand for chemical-free and gmo-free. We’re also moving toward non-toxic, vegetable-based dyes.

a)What about ethically?

We pay well above minimum wage to our employees and offer a safe and happy workplace.

7) What are the next steps for Groceries? How do you see yourselves evolving in the next five to ten years?

I see non-toxic and ethically-made clothing becoming the standard for our industry. Every step we take will be working towards this.